Modality brings the best of aerospace material evaluation back down to earth. Our comprehensive knowledge of non-destructive evaluation methods, combined with superior signal processing, is found nowhere else in today’s market. We combine our expertise to enhance analysis, guide design improvements, ensure defect-free manufacturing, and safeguard valuable assets.

Modality stands for clarity – that is why we do not just provide results; we deliver them in a way that is effortlessly understandable, empowering you with the insights you need to make informed decisions and act with confidence.

Advanced Material Inspections: Peering into the very heart of materials

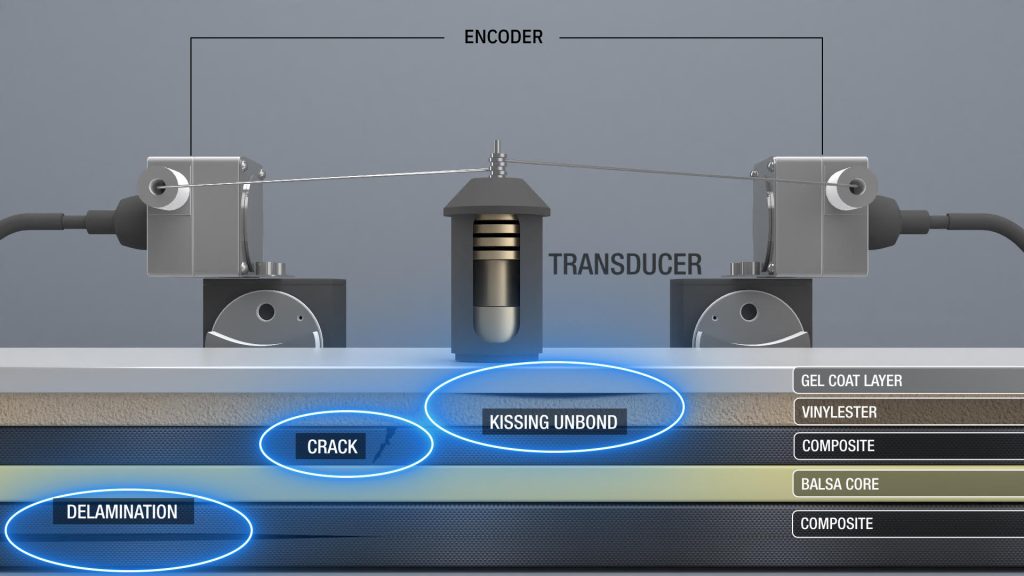

We harness sound waves to penetrate deep into materials, comprehensively detecting flaws. From locating composite unbonds to find cracks, ultrasound inspections is one of the most robust ways to ensure the safety and performance of critical components.

Modality’s is constantly pushing the boundaries of ultrasound innovation, developing cutting-edge technologies to ensure that every component meets the highest standards of quality, integrity, and safety. Our deep ultrasonic expertise, coupled with advanced technology developed for the NASA Orion capsule, allows us to uncover nuances that others cannot.

As technology progresses, materials evolve alongside it. However, not all ultrasonic inspections are created equal. Often, results are inconclusive due to insufficient knowledge. While some may conduct an ultrasonic inspection and assert that bondlines are joined, a Modality inspection will uncover the minimal separation that can lead to failure.

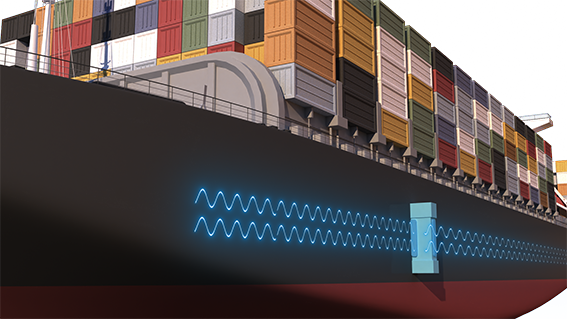

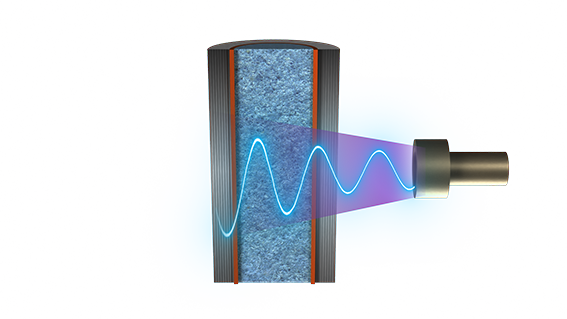

Guided Acoustic Waves: Inspect large areas from a single point

Guided waves offer the ability to inspect your entire structure from a single point, effortlessly uncovering hidden defects without causing any damage. Instead of point-by-point analysis, with guided acoustic waves, you achieve comprehensive, accurate results in one seamless sweep, covering large and hard-to-reach areas with ease. Conduct inspections without extensive downtime or safety precautions. With its high sensitivity a wide range of defects can be uncovered.

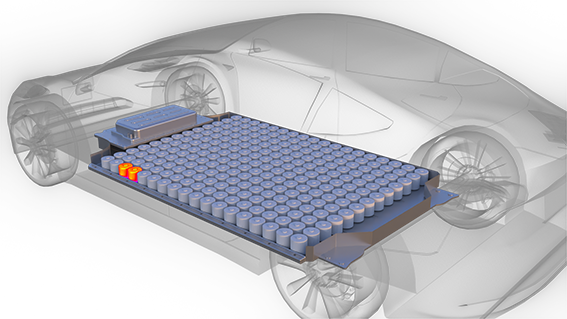

Infrared: Empowering ship crews to proactively defend lives & cargo

Defective lithium-ion batteries can cause thermal runaway, which results in a large, difficult to control fire that can reignite hours or even days after being extinguished. Modality designs and builds custom early warning systems, utilizing low-powered infrared sensors to continuously monitor cargo such as EVs for the signs that precede thermal runaway.

Our connected systems, which allow remote data access, alert crews to the exact location of any issue, where crews can take proactive safety measures to safeguard lives, cargo, and vessels. Modality enables detailed analytics which feed AI models to establish trends for preventive maintenanceModality helps ship owners and insurers maintain accurate records of battery performance, ensuring compliance with regulatory requirements.

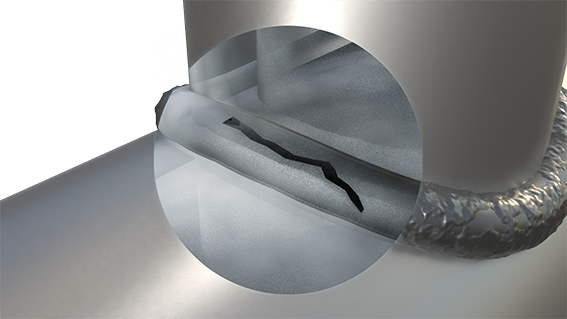

XRAY: Imaging for instant decision-making

With its unparalleled ability to penetrate metallic and non-metallic materials and provide detailed imaging, Modality X-rays precisely diagnose issues such as small crack propagation in a weld, foreign object debris, crushed core within a honeycomb structure, and other structural integrity issues, all with unparalleled imaging speed and efficiency.

The instant results available with Modality X-rays enable informed decision-making on the spot.

MICROWAVE: Inspecting non-conductive materials with remarkable precision

Materials technology is pushing boundaries with lighter, stiffer, and stronger materials replacing metals across the board. Most of these materials are non-conductive, foams, or glass fiber composites, which are easily penetrated with Microwaves, often without contact, and across large scan areas.

Microwave inspection from Modality reveals internal and surface defects including disbond corrosion, composite delamination, cracks hidden by coatings, and moisture with remarkable precision, while also providing insightful porosity estimates in ceramics and rubber.

SHEAROGRAPHY: Rapid detection of defects in metallics and composites

Accomplished by comparison of metallics and composites under small stress loads, Modality Shearography enables the precise inspection of complex geometries, composites, bondlines, and foams to detect barely visible impact damage. Modality analyzes surface topography to reveal defects including disbonds, delaminations, impact damage, porosity and wrinkling.

Protect valuable assets with our advanced non-destructive evaluation methods. Contact us today!